RMIT RPL APPLICATION

GLEN PITTOCK

STUDENT# S3854869

CAID TO CAM

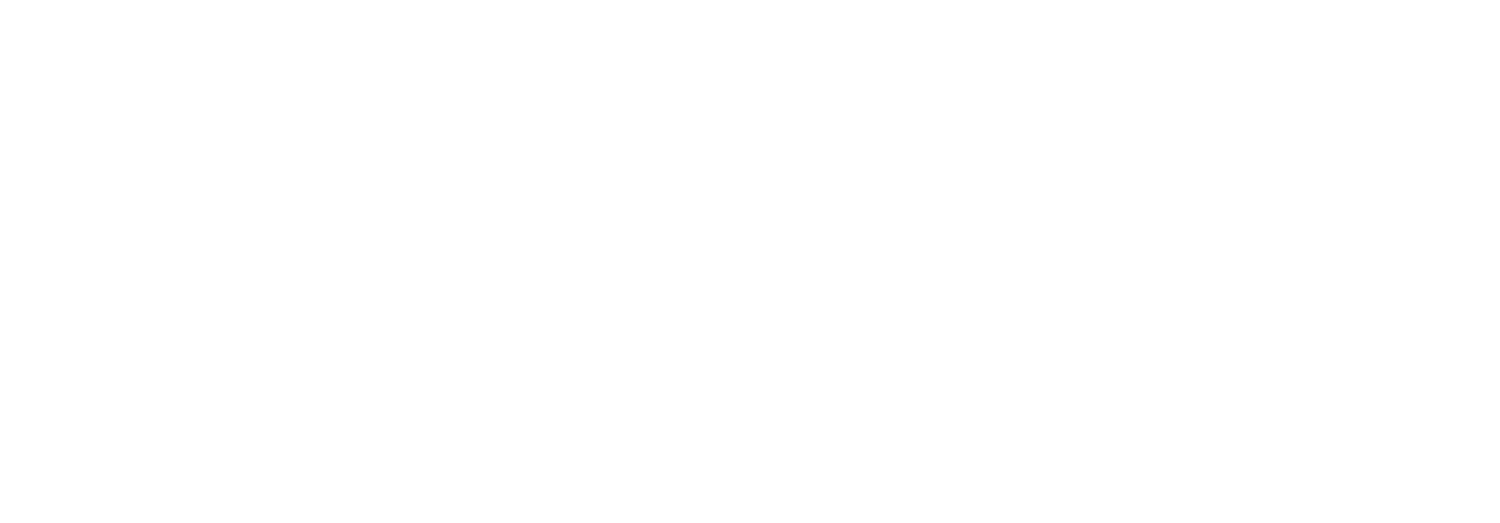

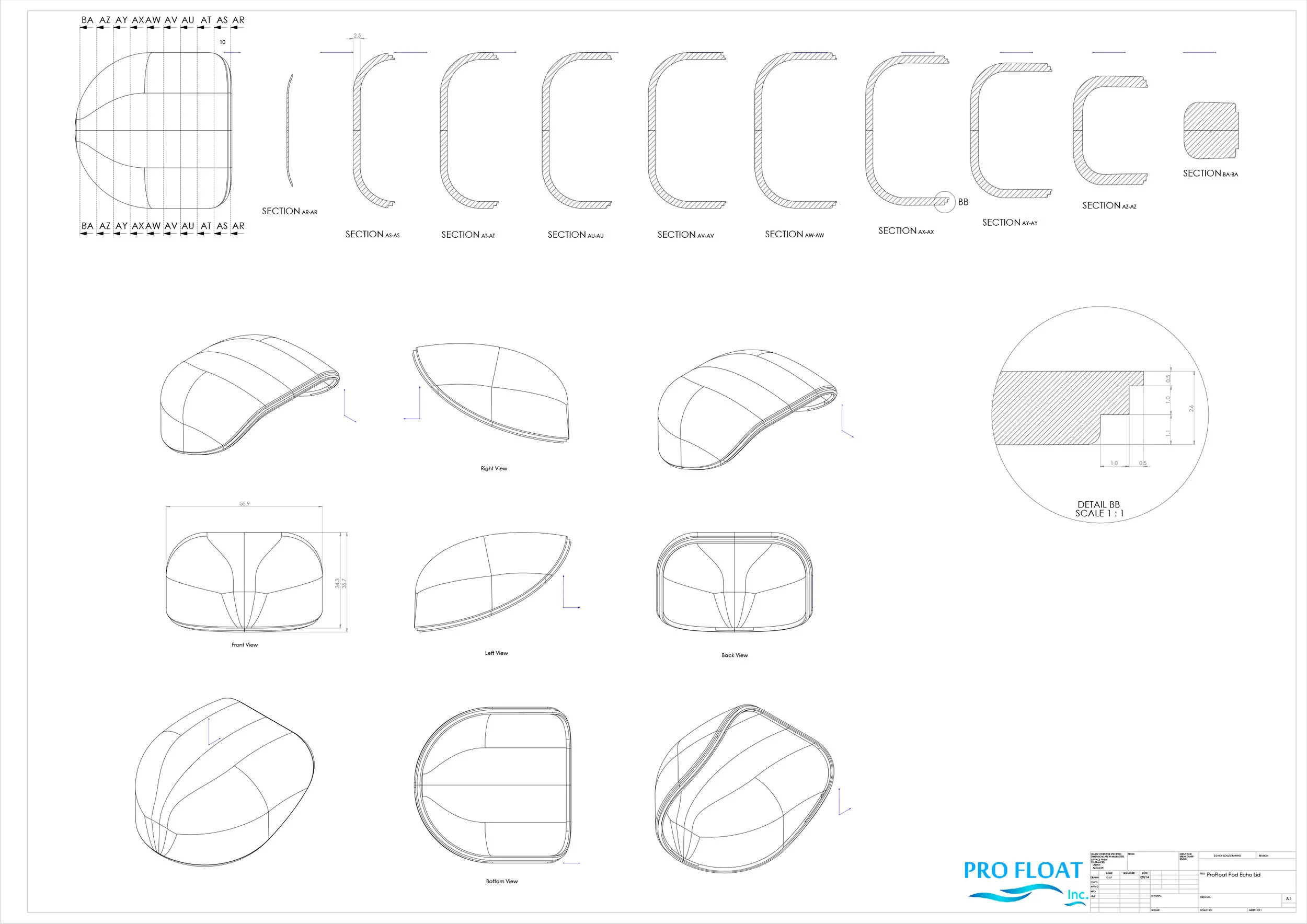

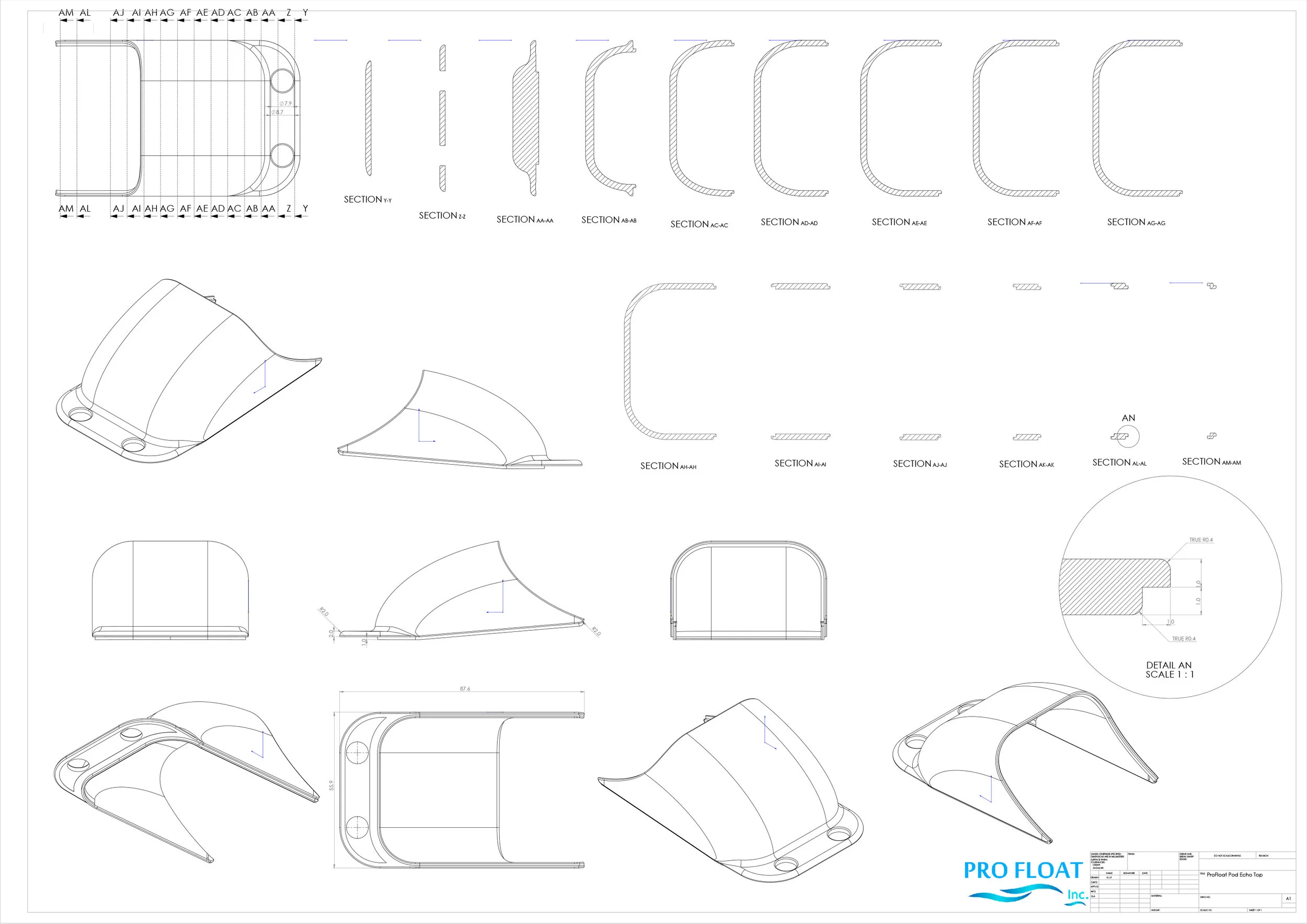

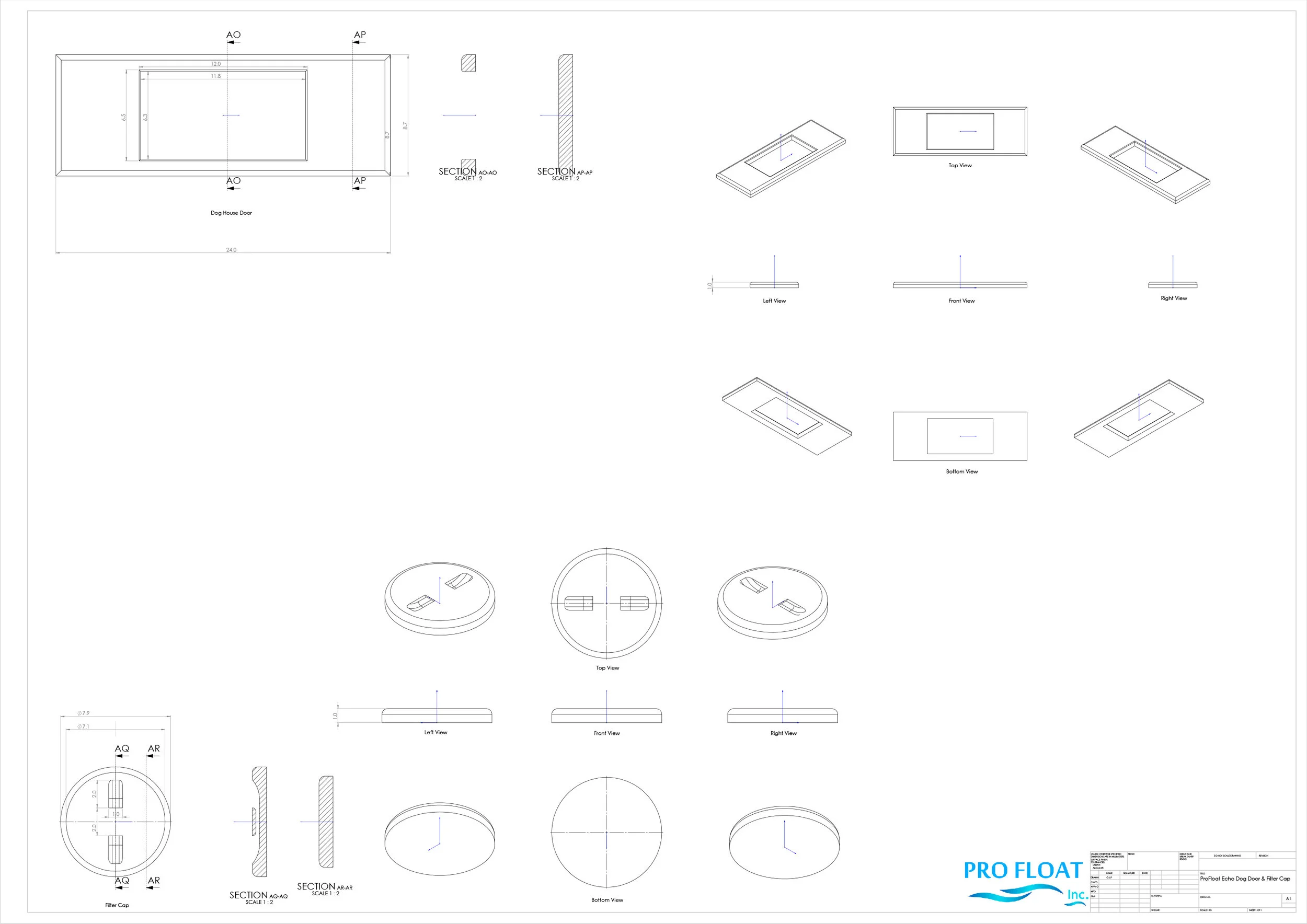

PROJECT: Sensory deprivation/float tank

type: work eXPERIENCE

client: pROFLOAT INC. - VANCOUVER, CANADA

RELEVANT SOFTWARE:

Desault solidworks

3d studio max

v-ray render

Formats: .sldprt, .sldasm, .slddrw, .3ds, .psd, .pdf, .stl, .dwg, .jpg, .avi

Hired as a CAD freelancer in 2014 via freelancer.com, Profloat Inc. based out of Vancouver, Canada recruited me due to my demonstrated CAD portfolio and experience with sensory deprivation tanks.

Over the course of 3 months I worked with Profloat’s Production Manager, Electronics contractor, and CNC contractor to develop a CAD model for CNC mold preparation through a series of design iterations, that would go on to be used for production fiberglass manufacturing.

The project was delivered in .SLDPRT, .SLDASM, . STL and technical drawing .PDF and .DWG formats.

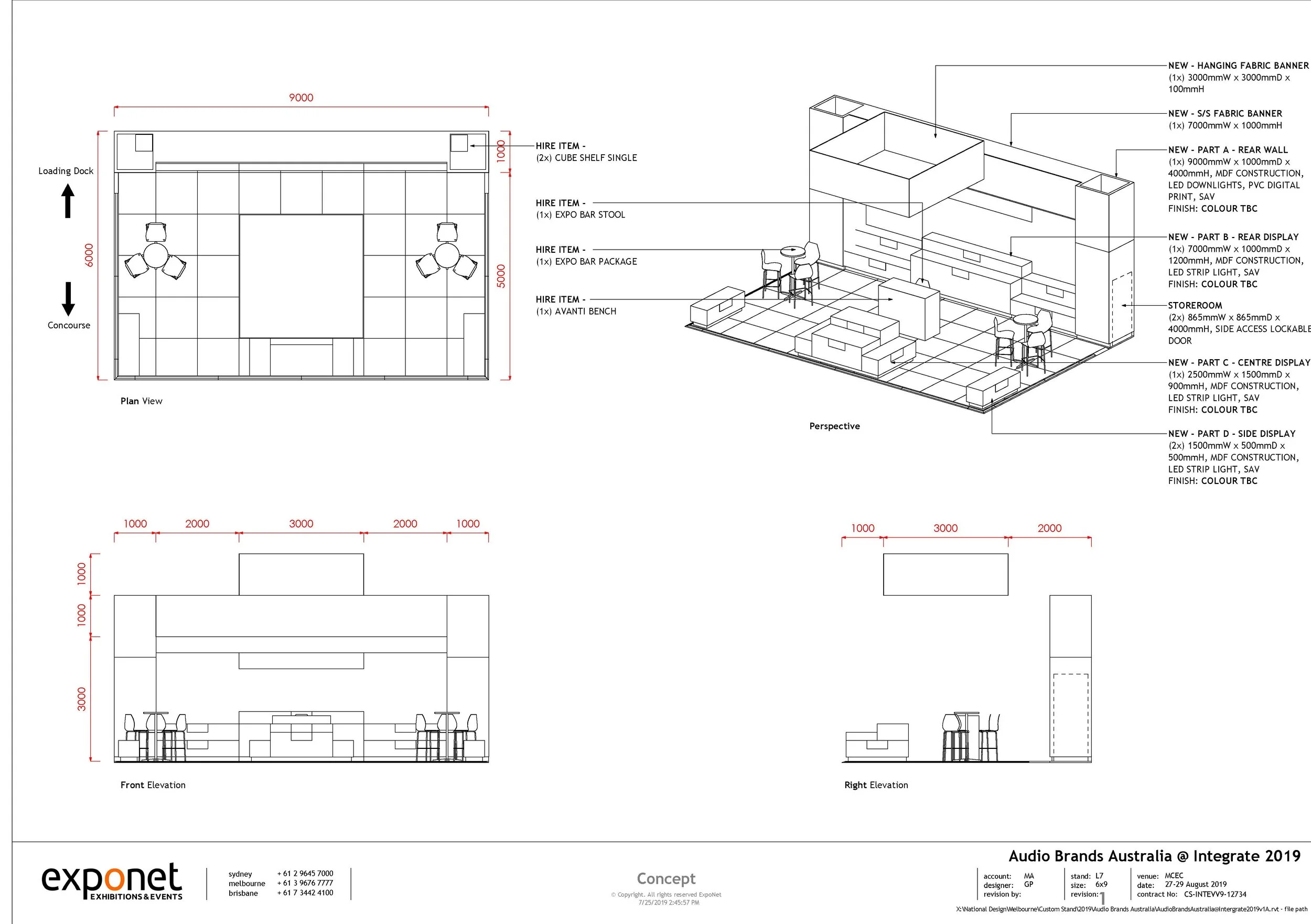

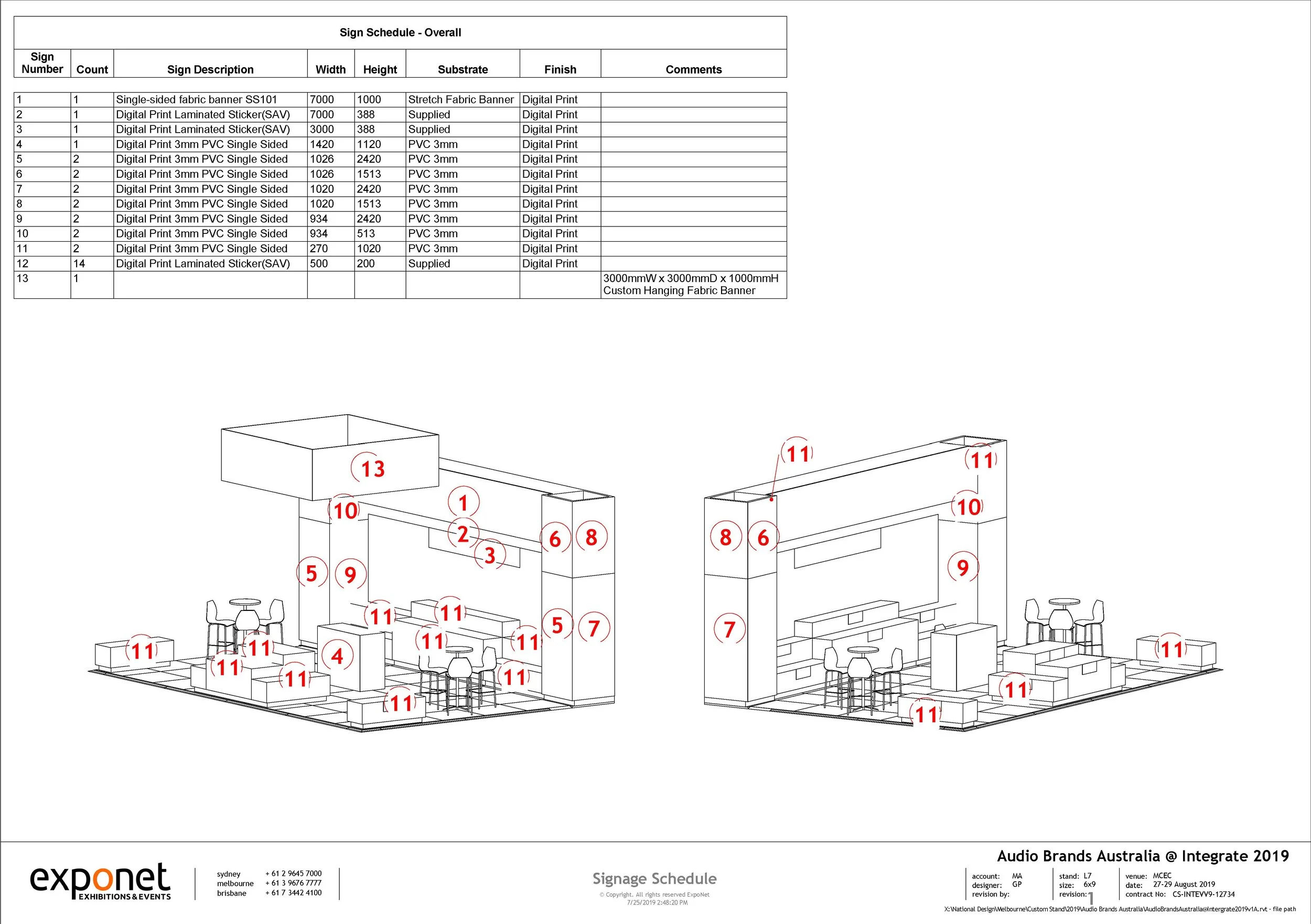

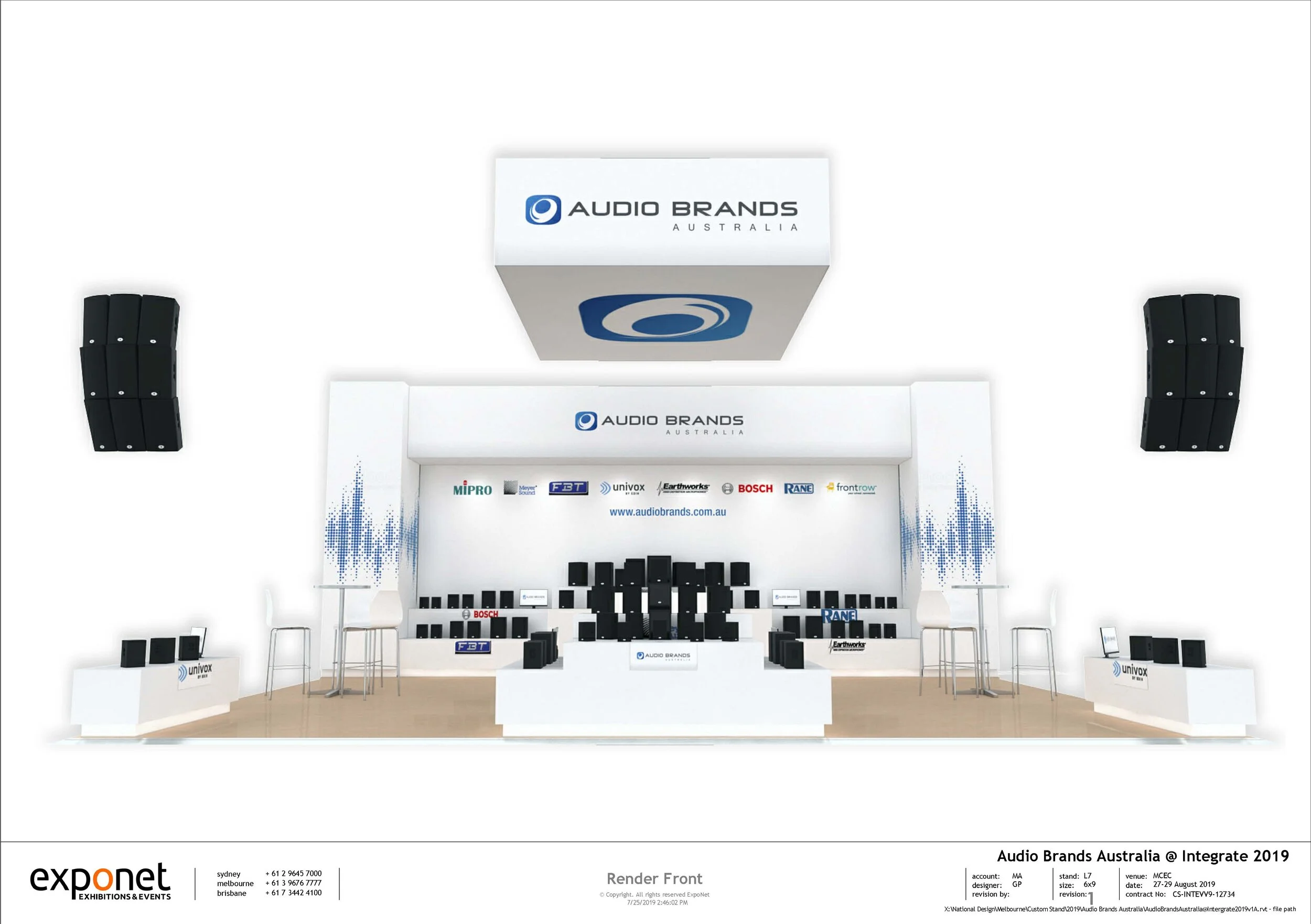

POsition: Senior custom exhibition designer

TYPE: Work experience

employer: exponet exhibitions

RELEVANT SOFTWARE:

Autodesk revit,

3d studio max

v-ray render

Formats: .rvt, .3ds, .psd, .pdf, .dwg, .jpg,

Recruited by Exponet Exhibitions National Design Manager, Ben Kaldor-Bull, I was charged with the role of leading the Custom Exhibition Design team to create custom design trade show exhibitions. I would utilize the above listed software while liaising with Account and Production managers to take designs from concept through to completion while adhering to project budgets and company OH&S standards.

Designs were delivered to to the production team in working constructions drawings. I would continue to oversee the designs through their production and installation stages, across Australia.

Project: angana bodhi - art installation

type: work eXPERIENCE

client: earthcore events

RELEVANT SOFTWARE:

z-brush

solidworks

ILLUSTRATOR

3d studio max

v-ray render

Formats: .obj, .sldprt, .sldasm, .slddrw, .3ds, pdf, .stl, .dwg,

Commissioned by Earthcore events for the 2015 Earthcore Music festival, I was given the brief to create the primary art installation of the festival to suit the theme of ‘Other Worlds’.

I would use concept sketches and Illustrations as a base to sculpt a 3D model using 3D Sculpting software Z-brush. This model would undergo a series of format alterations in order to convert to an editable solid body in which I would utilize Desault Solidworks to make alterations and output .DXF format for Waterjet cutting out of 5mm Alluminium sheet and .PDF format for on site assembly and installation.

Additional and notabale CAD components in the projects were the 'Globe mounts’ that were 3D printed and ‘Connection rods’ that were given to a machinist to chamfer and tap bolt hole threads in the ends.

Project: fractal floating - art installation

type: work eXPERIENCE

client: earthcore events

RELEVANT SOFTWARE:

Adobe illustrator

solidworks

ILLUSTRATOR

3d studio max

v-ray render

Formats: .AI, .sldprt, .sldasm, .slddrw, .3ds, pdf, .stl, .dwg,

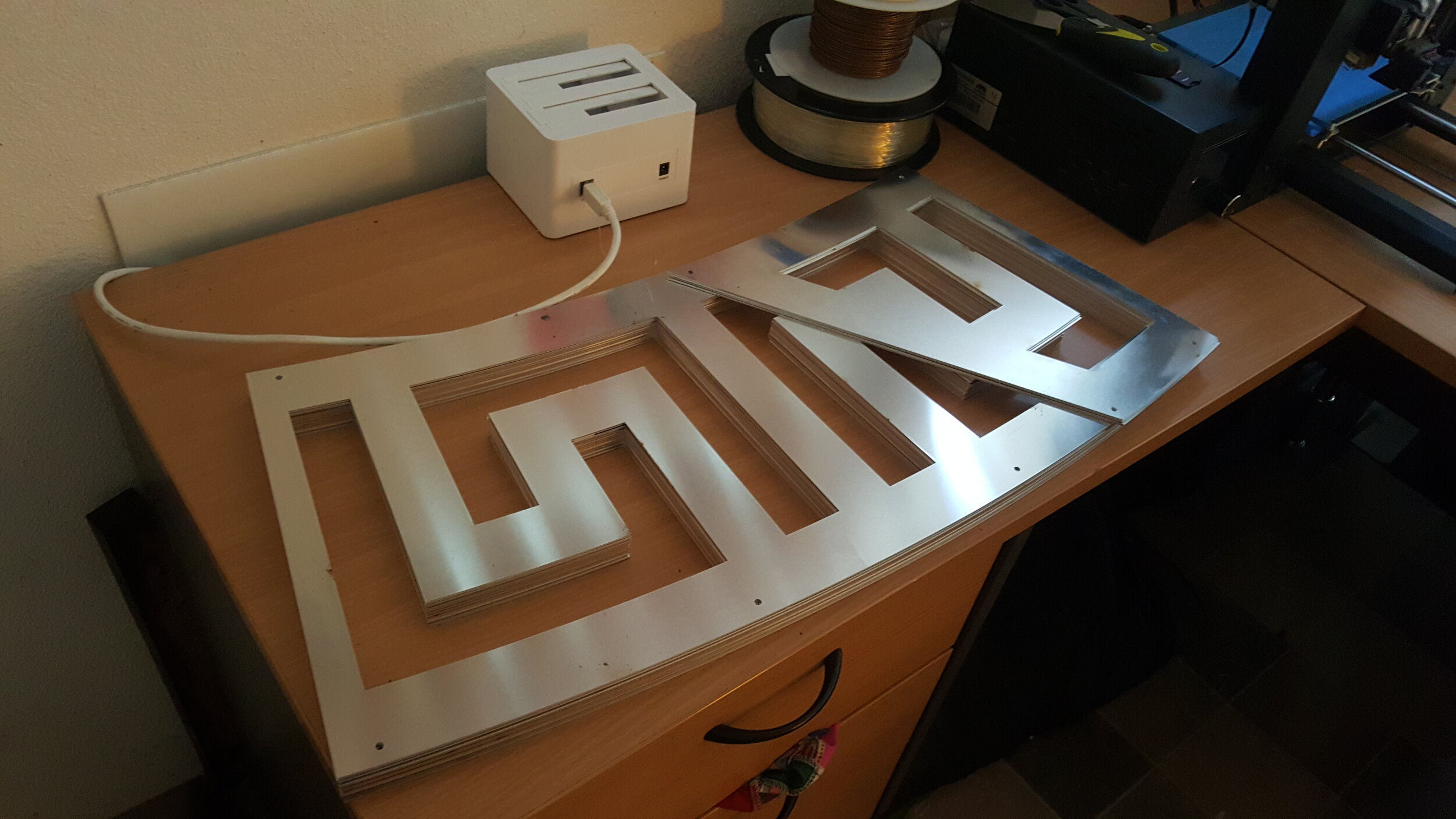

Commisioned by Earthcore events to create a back-to-back primary art installation to suit the brief of ‘Parallel Universe’ I would use Adobe Illustrator to create the pattern to be laser cut out of 1.6mm aluminium sheet, and solidworks to specify 25x25mm tube steel to be bent to specific radius, in order for fabrication of the frame.

Position: CAD ARTIST

type: work eXPERIENCE

client: cubia - self employed

RELEVANT SOFTWARE:

Zbrush

solidworks

ILLUSTRATOR

Fusion 360

3d studio max

v-ray render

Formats: .AI, .obj, .sldprt, .sldasm, .slddrw, .3ds, pdf, .stl, .dwg, .dxf

As a form of creative outlet, I would primarily use Z-brush and Solidworks as a platform to create a range of organic and geometric designs that I would submit to various CNC machines for processing in a range of materials, to assemble into art pieces to be sold across Australia and New Zealand. Notably one piece being commissioned to retiring R.S.P.C.A president, Dr Hugh J. Worth as his parting gift for 40+ years of loyal service.

Position: product developer/graphic designer

type: work eXPERIENCE

client: ACOL Industries

RELEVANT SOFTWARE:

solidworks

solidworks flow simulation

ILLUSTRATOR

3d studio max

v-ray render

Hired as the in-house graphic designer, my role quickly morphed into in-house product developer. I was tasked with training and upskilling in Desault Solidworks software, where I use these skills to develop Skylight and Roof window products for sale in Bunnings Warehouses across Australia.

Other notable CAD components during employment:

Jet unit 3D Scan and redsign for V8 Jetsprint boat that would go on to win the Australian Championship

Modificaion and/or rapid prototyping for in-house factory machine components.

Engine mounting system for V8 Jetsprint boat.

3D printer improvements.

Project: earth love-power bubble mill

type: LIFE eXPERIENCE

institution: rmit

RELEVANT SOFTWARE:

fusion 360

Photon-s 3d print software

3d studio max

corona render

RMIT Engineering Assignment 3 I designed and 3D Printed a wind powered gravity battery that would power a ‘bubble-mill’ that would blow bubbles once the battery is discharged.

PROTOTYPING

Project: earth love-power bubble mill

type: LIFE eXPERIENCE

institution: rmit

RELEVANT SOFTWARE:

fusion 360

Photon-s 3d print software

3d studio max

corona render

techniques:

3d resin printing

Bamboo construction

Wind testing

Stress testing

mechanical components

AESTHETICS design

RMIT Engineering Assignment 3 I designed and 3D Printed a wind powered gravity battery that would power a ‘bubble-mill’ that would blow bubbles once the battery is discharged.

This project was build specifically as a prototype in order to understand the functions and mechanisms required to build this pieces as a large scale art installation at the upcoming 2021 Esoteric music festival in Donald, Victoria.

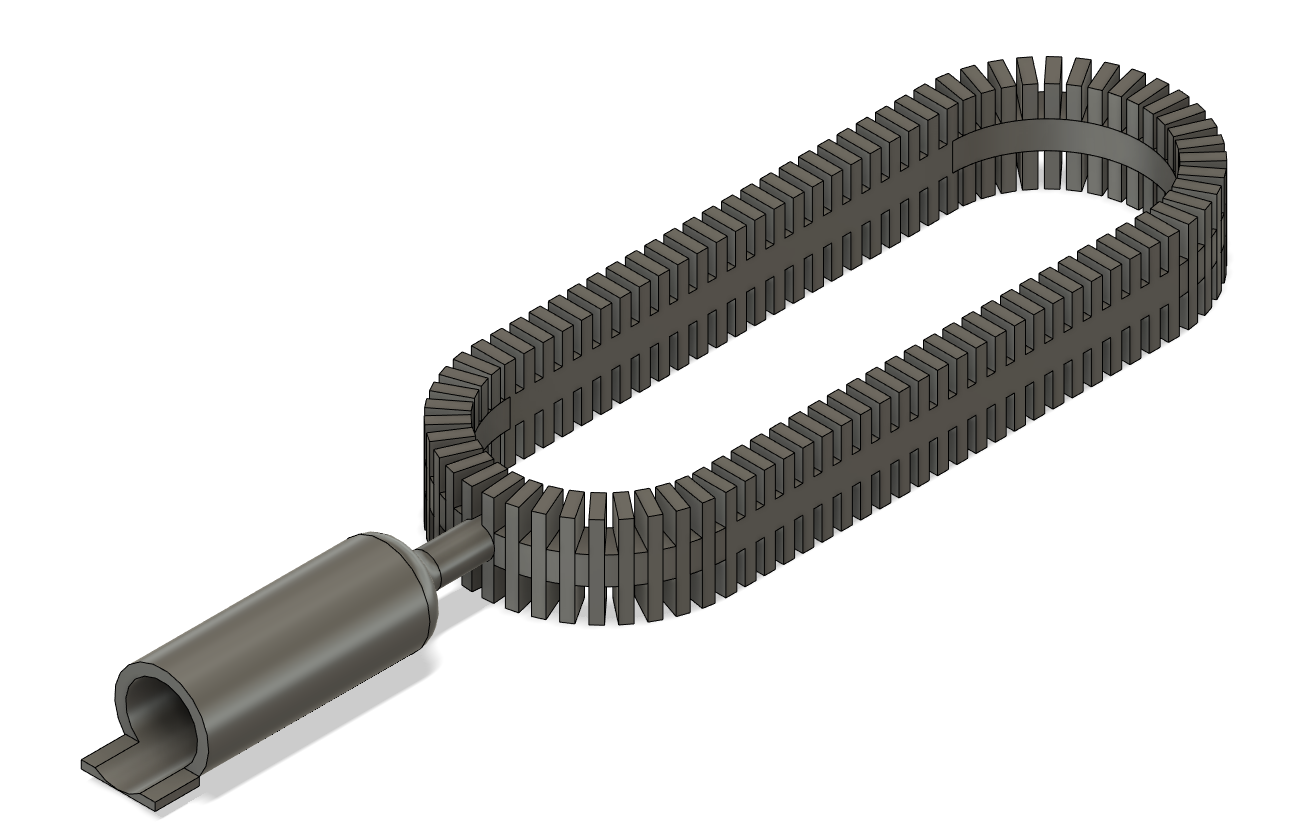

Project: samsung gear vr headset heat unit

type: work experience

client: cubia

RELEVANT SOFTWARE:

solidworks

cura print

techniques:

3d fdm printing

electric wiring

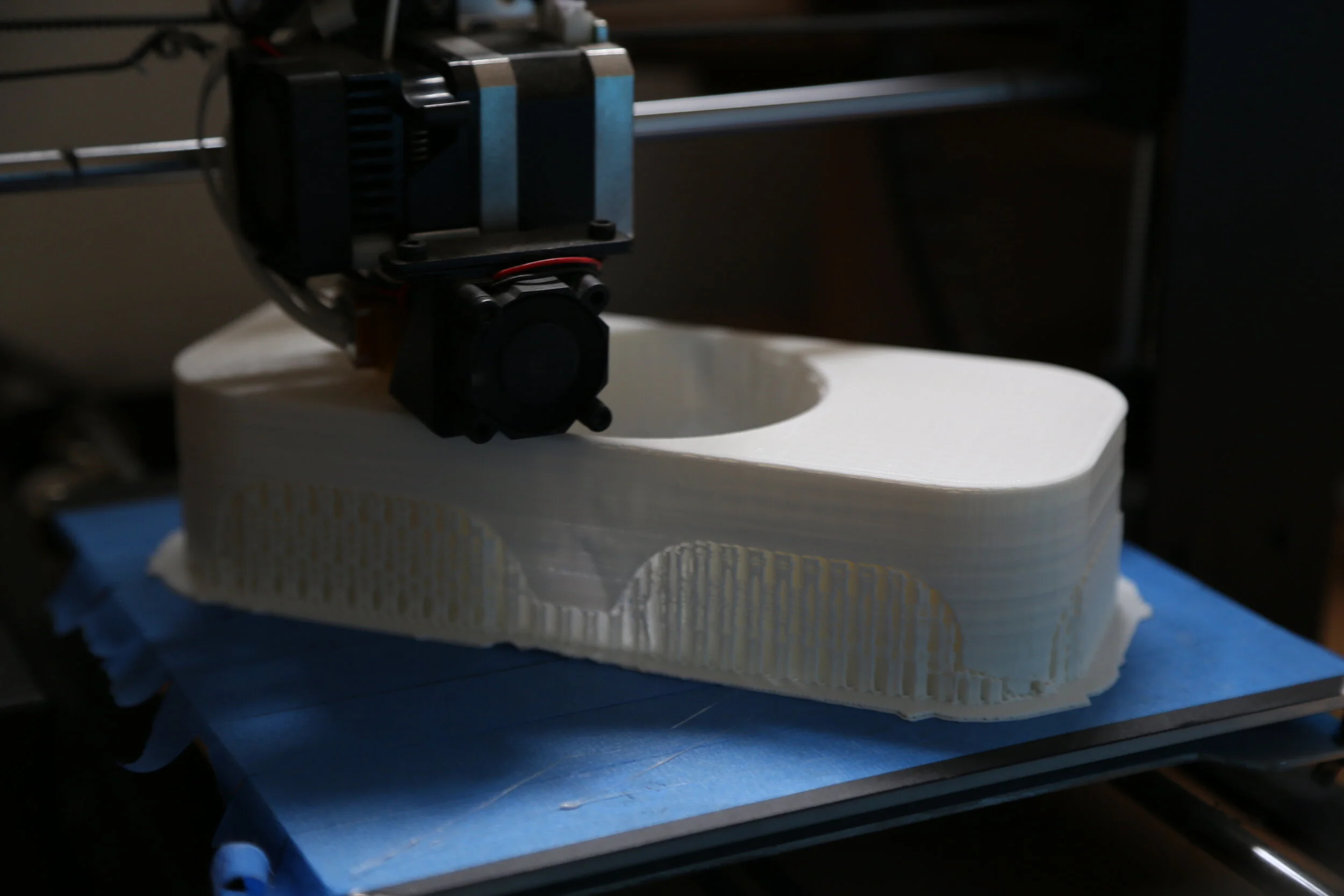

Contracted to run an immersive Virtual Reality experience over 36 combined hours in an environment renowned for it’s extreme heat conditions, an issue arose regarding the specified Virtual Reality headset - Samsung Gear VR and it’s known overheating issues - causing the unit to shutdown.

I set out to design and prototype a solution to resolve this issue.

The prototype involved designing a shroud to fit both the existing VR headset unit and sourced thin profile CPU fan.

4 iterations of the design involved tolerance testing, stress testing, safety features and light weighting to ensure the shroud and components did not subtract from the user experience.

The CPU fan was wired and soldered to fit a Micro-USB connection that was split fed from the main unit. On/off switch allowed disconnection of the operation when not required.

This design has been shared to 3D printing and VR websites and communities and has been utilized in various applications.

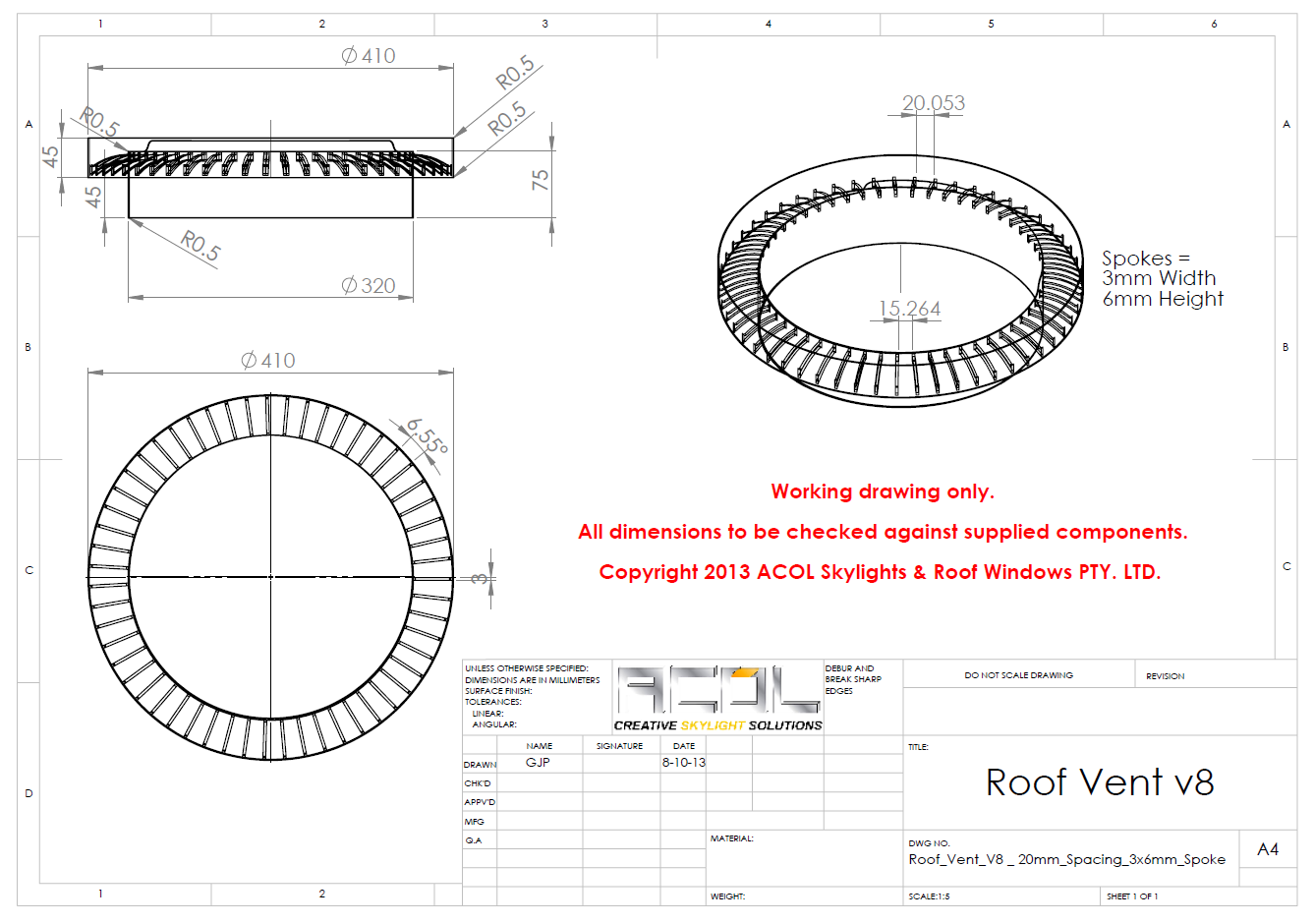

Project: static roof vent

type: work experience

employer: acol industries

RELEVANT SOFTWARE:

solidworks

Solidworks flow simulation

3d studio max

V-ray

illustrator

techniques:

3d fdm printing

electric wiring

Working directly with the company principle who identified an opportunity in the market, I would work from concept sketches to final product, inclusive of 3D modeling, 3D printing, virtual flow testing, CNC machinist, material and manufacturing processing and costing.

I would go on to design and arrange production and delivery of packaging for the units.

To date, over 10,000+ of these units have been sold through Bunnings Warehouses across Australia and New Zealand.

Additional units to this range included a range of Solar LED skylights, that I would work along side a contracted Electrical Engineer to develop a durability and stress testing program that we operated over the course of 6 months to ensure product warranties could be satisfied.

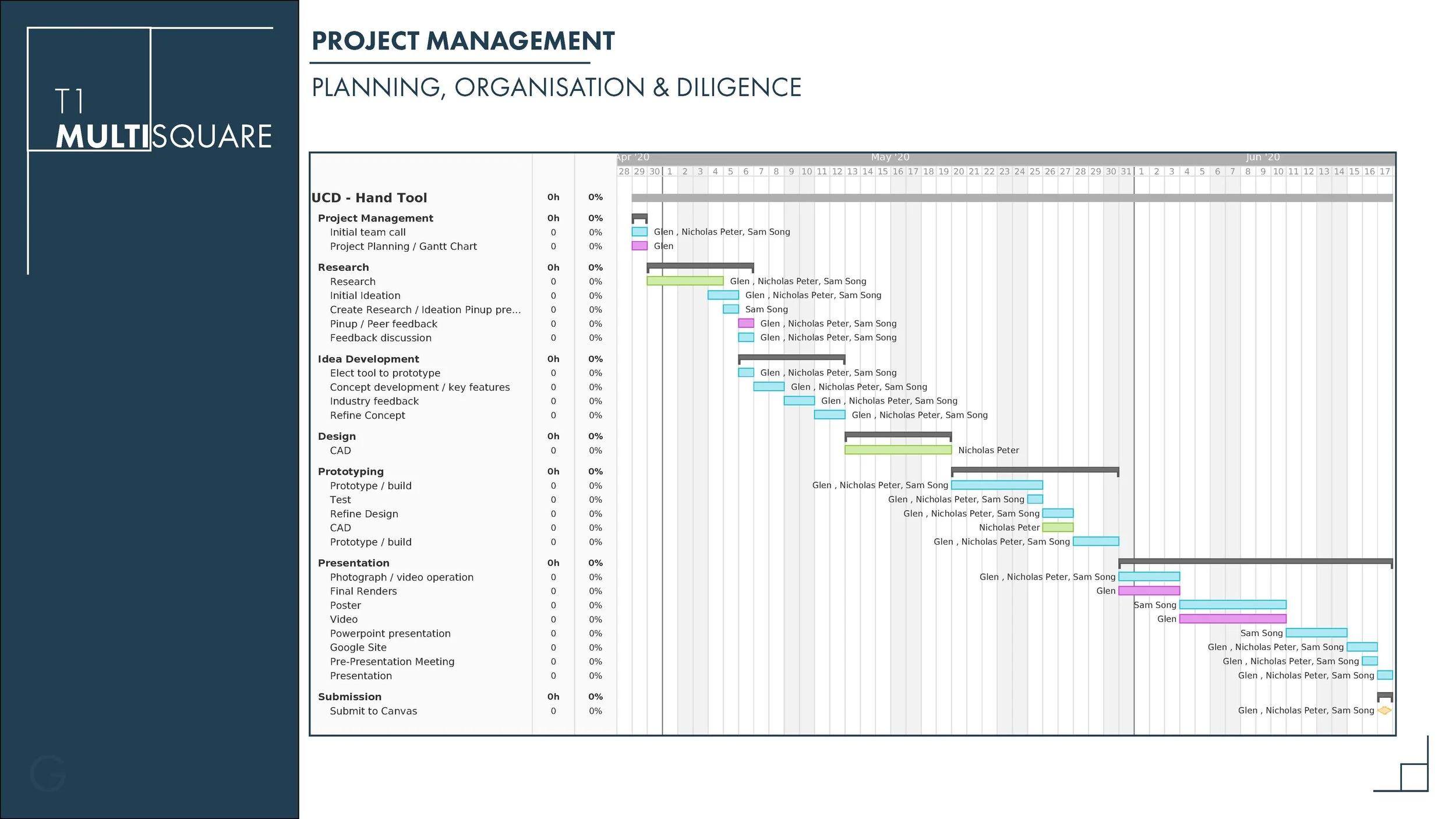

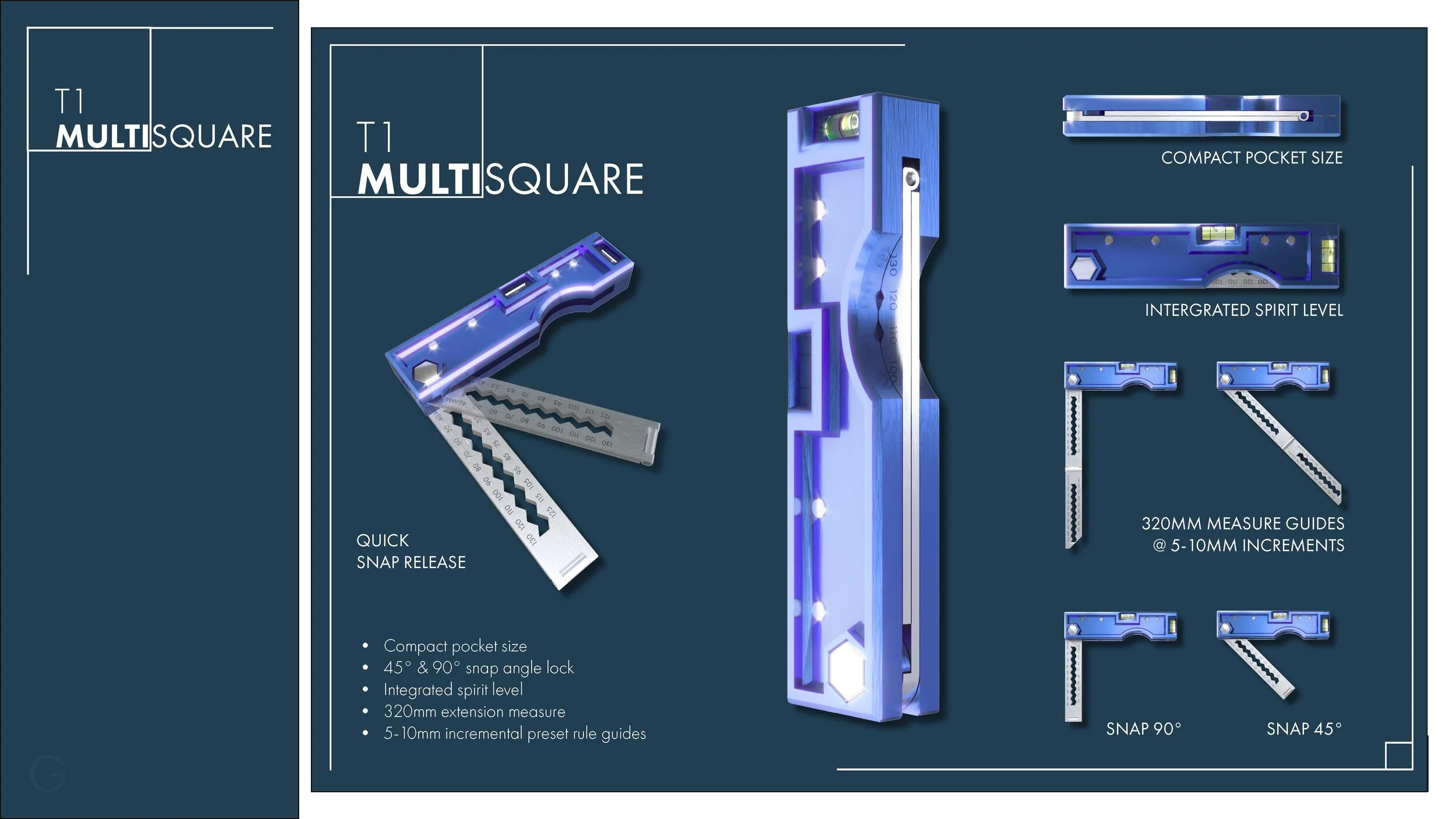

Project: t1 Multisquare

type: life experience

institution: rmit

RELEVANT SOFTWARE:

fusion 360

Photon workshop

3d studio max

corona render

photoshop

Illustrator

After effects

Adobe premiere

techniques:

ideation

Sketching

3d resin printing

tolerance testing

Stress testing

Design iteration

Visualisation

Tasked with identifying an opportunity in the market to develop a hand tool for a tradesman, we used various research methods to do so.

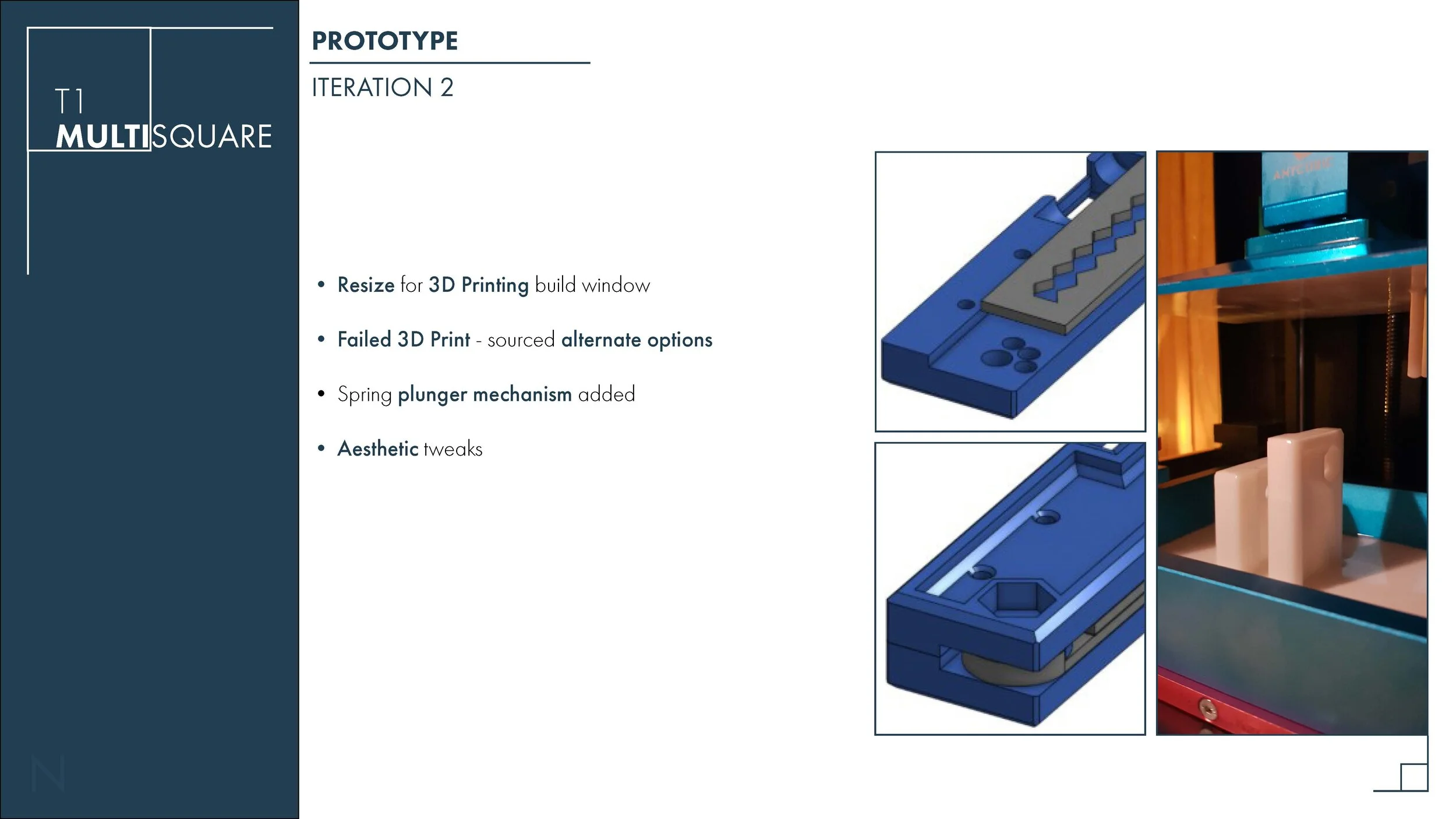

The design was taken from ideation sketches through to fully functioning prototype with a series of design iterations.

We are currently looking for the next required steps to take the product to market.